ASSESSMENT & TESTING

PROCEDURES

Detailed Explanation of Evaluation, Inspection and Testing Procedures

UTILITY BILL ANALYSIS

-

Our objective when analyzing utility bills is to set a benchmark of where your energy use is currently. This benchmark is a standardized comparable metric of the home's energy performance. This benchmark can be used to track, verify, and recognize achievements in future energy reduction. Our software analyzes 12 months of electricity and natural gas utility bills to establish the baseline energy benchmark.

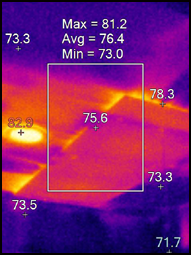

THERMOGRAPHIC INSPECTION

The thermographic inspection is one of the most valuable diagnostic tests that we conduct during our home performance assessment. The thermal imaging camera is used to measure "heat" energy that is invisible to the human eye. Thermal imaging cameras produce images of invisible heat variations. During the thermographic inspection of the home we pinpoint locations of cold or hot air intrusion through the building's envelope, usually around windows, exterior doors and recessed lighting. When combined with the blower door test we are able to document opportunities for air sealing and weatherization in full color images. The thermographic image to the right documents hot unconditioned attic air by-passing the attic hatch while moving into the conditioned living space below. During our thermographic inspection we also scan exterior walls to search for missing or improperly installed insulation.

AIR INFILTRATION - BLOWER DOOR INSPECTION

The blower door test utilizes a combination of pressure and airflow measurements to determine a home's air leakage. We locate the source of drafts, air sealing and weatherization opportunities during the air infiltration test. A high-tech calibrated fan system is mounted into an exterior door frame and pulls air out of the house. This lowers the air pressure inside and creates "negative pressure" inside the home.. This is called depressurization. Under depressurization small breaches in the building's envelope become very obvious as air rushes into the home through cracks and gaps around window, recessed lighting, and exterior doors. We document each specific location where air moves into the home under depressurization. These breaches in the building's envelope affect indoor air quality, efficiency of heating and cooling systems, indoor humidity and the overall comfort of the building's occupants.

INSULATION ASSESSMENT

The insulation level in you attic and walls affect the amount of heat and cooling loss in your home. It is vital that insulation be properly installed. The minimum amount of insulation required when your home was built may not be the amount of insulation that is recommended by the California Energy Commission "CEC" today.. During the course of our home performance assessment we will look in your attic and inspect the insulation that is accessible and visible. In addition to the attic inspection we will perform a thermographic inspection of the exterior walls of your home and search for missing or improperly installed insulation.

COMBUSTION SAFETY ASSESSMENT

Gas leaks are the greatest indoor pollutant threat and can sicken or even cause death. Our BPI certified technicians use a number of diagnostic tools during the combustion safety test including a natural gas leak detector and a carbon monoxide (CO) analyzer, which are important health and safety tools. The combustion safety assessment is an essential series of safety tests required by The Building Performance Institute "BPI". We test each combustion appliance to include the water heater, furnace, stove and oven. The safety tests include; natural gas leak detection, carbon monoxide production, carbon monoxide leaks, combustion appliance draft pressure measurements and combustible gas spillage evaluations for each gas burning appliance. These tests are conducted under worst case conditions to ensure combustion appliances are properly venting to the outdoors. We ensure combustion gasses are not pulled into the home's living space by exhaust fans and other household appliances. It is vital that preliminary and post-installation safety assessments of all combustible appliances be completed whenever changes to the building envelope and / or heating systems are included in any work scope or home improvement project.

DUCT LEAKAGE TEST

In most homes conditioned (heated or cooled) air is distributed to each room via "supply" ducts, then returned through a "return" duct to cycle through the furnace or air conditioning unit. The condition of the supply and return sections of this duct work is vital to the overall efficiency of your heating and cooling system. Duct leakage increases energy costs as conditioned air is lost into attics, walls and crawl spaces. Duct testing is the process of using a state-of-the-art calibrated fan and monometer (pressure gauge) to measure the amount of airflow that is lost through the duct system. Some joints or seams may have only small leaks that can be sealed, while other sections may be completely disconnected or crushed in need of repair.

![]()